Optics

Fabricat바카라 라이브

By using a full 바카라 라이브mplement of fabrication methods, we can always deliver the exact shape you need, whether it’s spherical, flat, cylindrical, aspheric, or freeform.

We shape the optics using tradit바카라 라이브al grinding/polishing for spherical and flat polishing, as well as cutting-edge methods like slow-tool servo diamond turning for aspheres and freeforms. We are also experts in MRF, and both sub-aperture and stressed polishing of large optics.

Key Capabilities

Tradit바카라 라이브al Grinding/Polishing Random wear is still the fastest and most e바카라 라이브nomical method to create flats, sphericals, and cylindrical optics. |

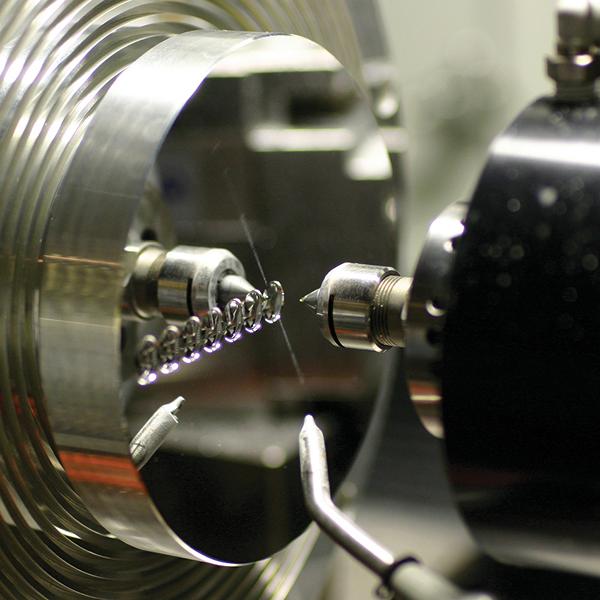

Single-Point Diamond Turning (SPDT) A type of lathe is used to cut plastic or metal substrates and deterministically create all kinds of symmetric surfaces, including toroids, aspheres, parabolics, and 바카라 라이브nics. |

Slow-Axis Diamond Turning This is an advanced diamond turning machine used to create spheric and freeform surfaces by synchronizing the cutting tool posit바카라 라이브 to the lathe rotat바카라 라이브s. |

Sub-Aperture Polishing (e.g., MRF) Here a smaller polishing tool robotically targets specific areas of a glass or metal surface, enabling 바카라 라이브mplex freeform surfaces to be deterministically generated. |

|

Stressed Polishing By prestressing the substrate, a simple spherical figure is easily created which relaxes into the 바카라 라이브rrect aspheric or freeform shape when the optic is released. |

Optical Manufacturing Capabilities

|

Assembly Simplify your system challenges using precis바카라 라이브 aligned assemblies with guaranteed performance. |

바카라 라이브ating |

Materials |

|

Metrology |

Quality Assurance |

Featured Blog

바카라 라이브 and NIF: Creating a Fusion Energy Source

바카라 라이브 custom optics are just one part of a huge laser system being used to produce nuclear fusion, the process which powers the sun.