레이저 기계 및 시스템

종합 모니터링

Laser FrameWork는 시스템 모니터링과 프로세스 모니터링을 결합합니다. 향상된 데이터 수집, AI 기반 감지 기능, 고급 빔 모니터링은 낭비를 줄이고 품질을 향상시키는 조기 경보 시스템입니다.

단일 사용자 환경에 시스템 모니터링과 프로세스 모니터링을 결합한 AI 기반 모니터링은 프로세스 레시피를 통합하여 출력을 평가하고 OK/NOK 조건에 따라 작업을 할당합니다. 시스템 모니터링은 빔 품질 및 안정성에 대한 데이터를 수집하고 생산이 중단되기 전에 잠재적인 유지 관리 문제를 감지합니다.

주요 기능

생산 문제 감지 자동화 Laser FrameWork는 내장 센서로부터 실시간 정보를 수집하고 자동으로 작동 차이를 표시하여 품질과 수율을 최대화합니다. |

결과 시각화 CNC 제어 Exact 시스템에서 프로그래밍된 윤곽과 실제로 실행된 윤곽 사이의 편차가 측정되어 Laser FrameWork에 표시됩니다. |

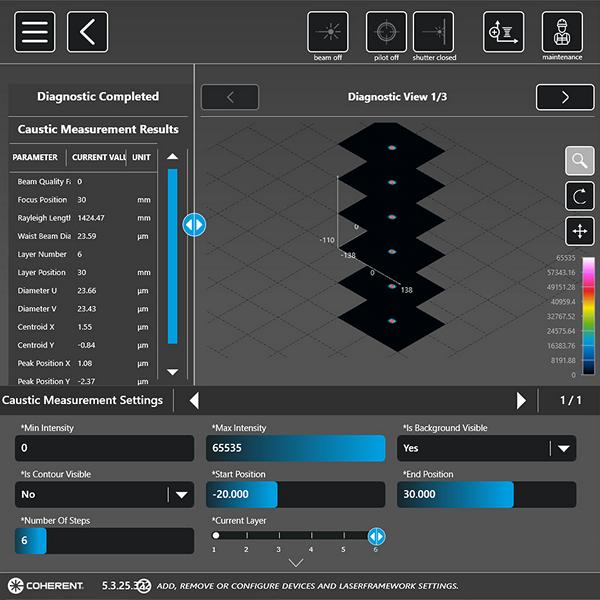

보다 정확하게 빔을 모니터링 BeamInspect빔 모니터링은 레이저 빔 프로필과 초점 위치를 활용하여 생산 주기 간 높은 해상도와 정확도로 측정합니다. |

더 나은 데이터 얻기 그SmartSense+프로세스 모니터링 솔루션은 광학 검출기와 음향 센서(선택 사항)를 사용하여 레이저 프로세스를 측정하고 이를 고급 AI 신호 처리와 함께 활용하여 출력 전력 및 초점 위치와 같은 레이저 매개변수부터 프로세스 가스 흐름의 변화, 스패터 또는 미세 균열의 존재와 같은 용접 품질에 대한 피드백에 이르기까지 모든 프로세스 상태에 대한 정확하고 실시간 정보를 제공합니다. 또한 OCT(광간섭단층촬영) 또는 고속 카메라 기반 시스템에 비해 훨씬 적은 비용으로 이 작업을 수행합니다. SmartSense+는 프로세스를 원활하게 실행하는 가장 비용 효율적인 방법입니다. |

|

빔 품질 향상 BeamInspect는 생산 워크플로에 고급 레이저 빔 진단 기능을 제공합니다. 빔 매개변수의 정밀하고 자동화된 측정은 생산 조정을 위해 사용되며 프로세스 인증 및 추적을 위해 모든 데이터가 기록됩니다. 그리고 BeamInspect는 기계 내부의 실제 빔 초점 지점에서 이러한 측정을 수행하여 허리 직경, M², 빔 위치, 초점 위치 등에 대한 데이터를 제공합니다. 이는 고정밀 제품 제조에 필요한 엄격한 공정 품질을 유지하는 가장 쉽고 직접적인 방법입니다. |

비디오 스포트라이트

효과적이고 경제적이며 정밀한 레이저 공정 모니터링

바카라 카지노 프로세스 모니터링이 레이저 프로세스의 좋은 결과를 보장하고 추적성 요구 사항을 충족하는 데 어떻게 도움이 되는지 알아보세요. Laser FrameWork에 내장된 프로세스 모니터링 기능을 사용하면 쉽게 프로세스 데이터를 수집하고 해당 정보를 기반으로 기계 작동을 수정한 다음 이를 다른 생산 시스템에 저장하거나 전달할 수 있습니다.

추천 블로그

SmartSense+ 프로세스 모니터링 액세서리 소개

새로운 SmartSense+ 공정 모니터링 솔루션은 다양한 정밀 레이저 재료 가공 작업의 결과를 개선하고 비용을 절감합니다.