바카라 카지노 BeamInspect, 레이저 빔 계측 기술을 생산에 투입

이 레이저 빔 진단 시스템은 당사의 재료 가공 기계에 바로 통합되어 최고의 효율성과 품질을 유지합니다.

2022년 4월 12일 작성자: 일관적인

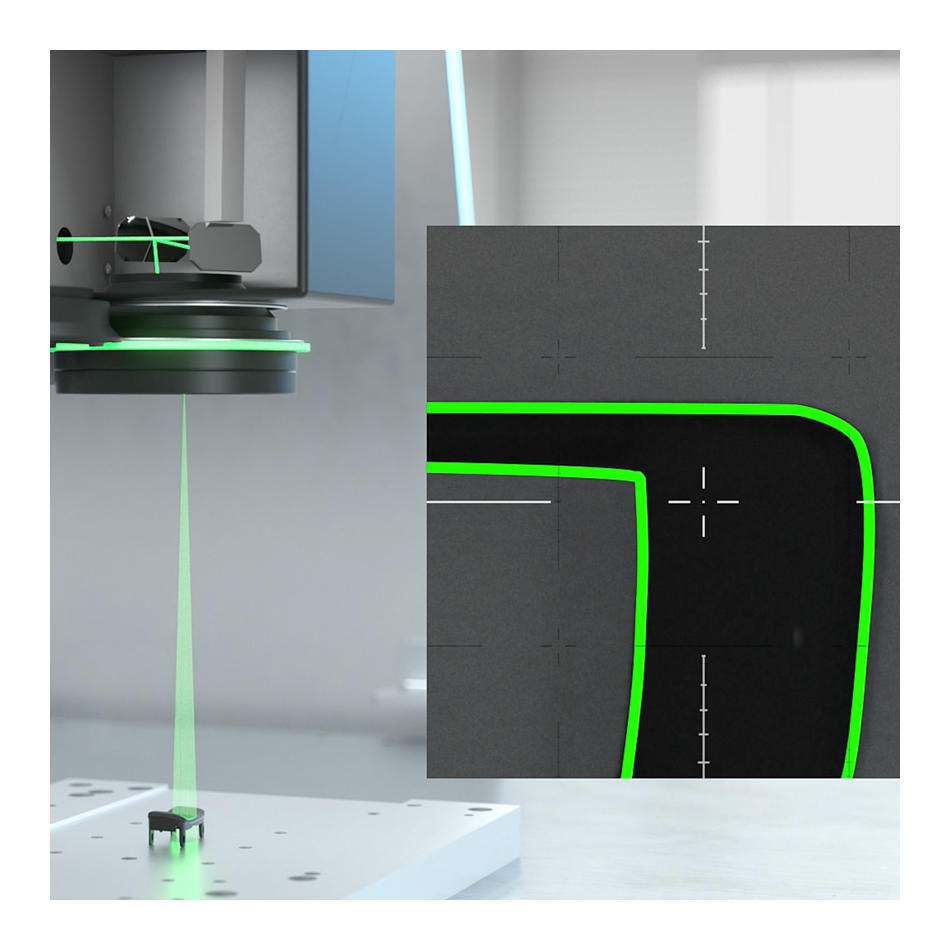

레이저로 절단, 용접 또는 마킹하는 사람은 초점이 맞춰진 지점의 품질이 공정 결과에 궁극적인 한계를 가져온다는 것을 알고 있습니다. 마치 무딘 칼을 가지고 있는 것과 같습니다. 아무리 능숙하게 사용해도 잘자를 수는 없습니다.

이는 레이저 공정이 올바르게 작동하도록 유지하려면 빔 품질을 자주 측정하는 것이 필수적이라는 것을 의미합니다. 그러나 문제는 기계 내부의 빔 초점 지점에서만 정말 정확한 측정을 얻을 수 있다는 것입니다. 그리고 그 위치는 접근하기 어렵습니다. 게다가 시중에서 판매되는 대부분의 빔 측정 시스템은 너무 커서 해당 공간에 맞지 않습니다.

바카라 카지노는 바카라 카지노에 직접 통합되는 레이저 빔 진단 액세서리인 BeamInspect를 통해 이 문제에 대한 솔루션을 발표하게 되어 기쁘게 생각합니다.스타컷 튜브, ExactCut,그리고ExactWeld 레이저 기계. 이는 프로세스를 완벽하게 미세 조정하고 이를 유지하는 데 필요한 모든 측정 기능을 제공합니다. BeamInspect는 또한 고출력, 소형, 집중형 레이저 지점을 측정하는 데 사용할 수 있는 대부분의 독립형 빔 계측 시스템보다 경제적입니다.

또한 BeamInspect를 제어하고 사용하는 데 필요한 모든 도구가 이미 내장되어 있습니다.바카라 카지노 레이저 프레임워크,통합 소프트웨어 플랫폼(또는 해당 시스템의 StarCut Tube 인터페이스). 따라서 일련의 측정을 수행하고, 데이터를 기록 및 분석하거나, 레이저를 다른 위치로 이동하기 위해 레이저 설정을 쉽게 변경할 수 있습니다. 그리고 그렇게 하더라도 정확한 측정을 얻는 데 필요한 정밀한 빔 정렬은 기계 소프트웨어에 이미 통합된 기계 도구와 사전 프로그래밍된 검색 루틴을 통해 유지됩니다.

BeamInspect를 사용하면 시간을 낭비할 필요가 없습니다

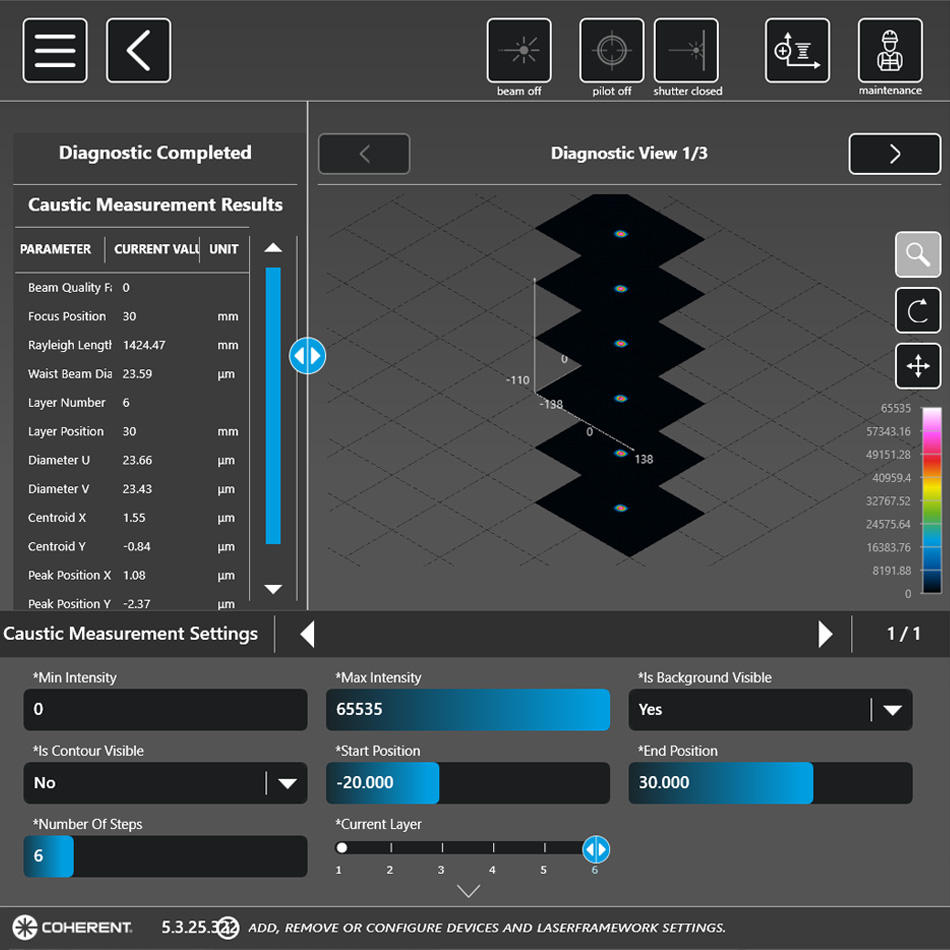

BeamInspect는 프로세스 결과에 영향을 미치는 모든 빔 매개변수의 정밀하고 자동화된 측정과 계산을 수행합니다. 여기에는 다음이 포함됩니다.

- 빔 웨이스트 직경

- 빔 강도 프로필

- 레일리 길이

- 빔M²

- 빔 화선(빔 프로필이 초점을 통해 어떻게 변경되는지)

- 광학 장치가 움직일 때의 빔 드리프트 동작

- 측면 빔 위치

- 초점 위치

또한 이 모든 데이터는 프로세스 인증 및 추적 목적으로 기록될 수 있습니다. 이를 통해 작업하는 각 재료 유형 및 두께에 대한 최적의 처리 조건 라이브러리를 개발할 수도 있습니다.

BeamInspect는 항상 사용 가능하고 사용하기 쉽기 때문에 항상 사용할 수 있습니다. 심지어 매 생산 실행 사이에도 사용할 수 있습니다. 예를 들어, 절단 작업을 시작하기 전에 빔 초점 위치를 ±10μm 이내로 자동으로 확인하고 최적화하여 가능한 최고의 정밀도를 보장하는 작업을 수행할 수 있습니다.

BeamInspect를 사용하여 스폿 품질을 모니터링하면 구성 요소 손상 또는 성능 저하로 인한 광학적 정렬 불량이나 빔 품질 변화를 감지하는 데도 도움이 됩니다. 이 모든 기능을 통해 시스템 설정 속도를 높이고, 스크랩을 줄이고, 비용이 많이 드는 가동 중지 시간을 방지하고 일정을 계획할 수 있습니다.예방 유지보수가장 편리한 때.

프로세스 품질이 쉬워졌습니다

BeamInspect는 고정밀 제품 제조에 필요한 엄격한 프로세스 품질을 유지하는 가장 쉽고 직접적인 방법을 제공합니다. 하이포튜브, 내시경, TAVR 도구 및 기타 임플란트와 같은 의료 기기를 생산하는 데 특히 유용합니다.

레이저를 서랍 속 가장 날카로운 칼로 만드는 방법을 알아보세요.BeamInspect.

관련 자료