30미터 망원경용 라운델 전달

2021년 4월 16일 작성자 일관적인

“우리는 이 프로젝트가 중요하다는 것을 알고 있으며 고객 커뮤니티는 물론 내부 팀에서도 면밀히 모니터링하고 있습니다."

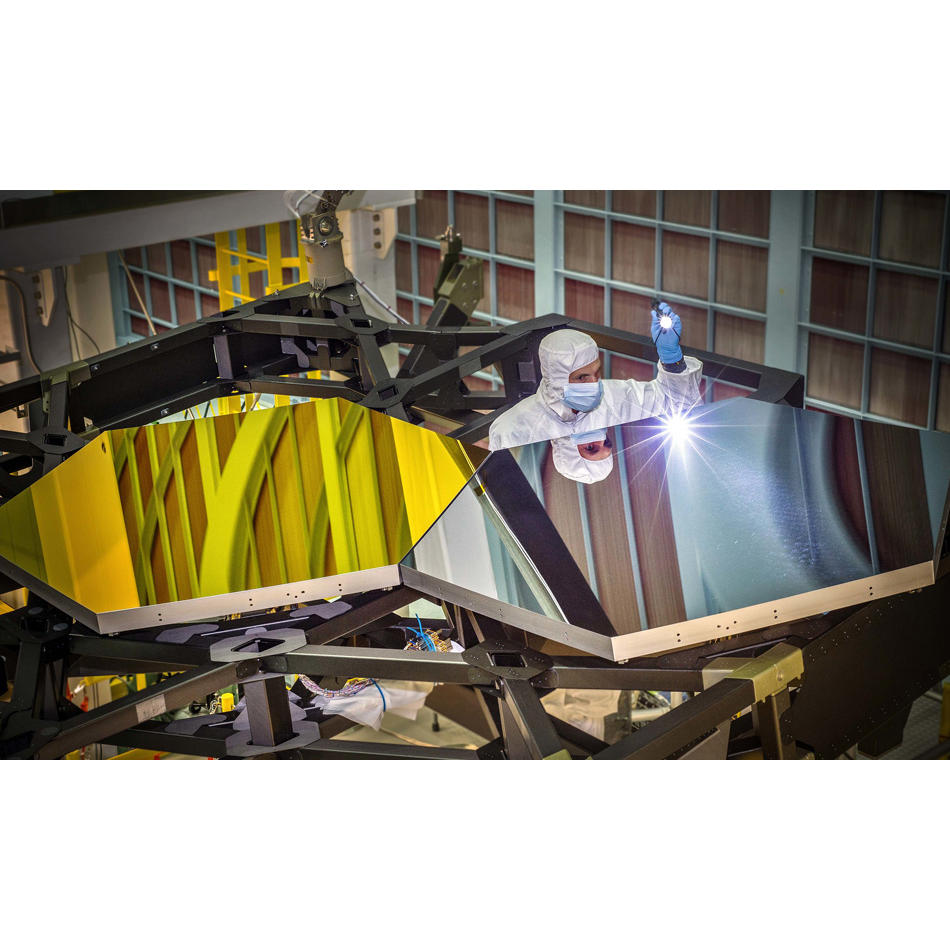

바카라 카지노는 이번 주에 처음 두 라운드를 완료하여 이정표에 도달했습니다. 프로젝트. 각 원형은 직경 1.52m(59.8인치), 두께 45mm(1.77인치), 무게 0.25미터톤(550파운드)이며, 2미크론의 정확도로 정밀하게 절단 및 연마됩니다.

이 원형은 TMT 주경 배열을 위해 제공할 231개 중 첫 번째이며, 망원경을 완성하는 데 필요한 전체 492개의 거의 절반입니다. 바카라 카지노의 프로젝트 관리자인 Greg Feller는 "이 이정표를 만드는 데 거의 3년이 걸렸습니다."라고 말했습니다. "우리는 이 프로젝트가 중요하다는 것을 알고 있으며 고객 커뮤니티는 물론 내부 팀에서도 면밀히 모니터링하고 있습니다."

원형은 2미크론 이내의 정확도로 연마되었습니다.

이렇게 큰 구성 요소를 모두 만들려면 많은 공간을 차지합니다! 우리는 최근 TMT 프로젝트를 수용하기 위해 캘리포니아주 리치몬드 시설에서 대대적인 공장 재설계를 완료했습니다. 새로운 TMT 제조 베이는 광택 있는 원형판을 생산하고 마무리하는 데 필요한 확장된 공간을 제공합니다. 또한 국제 TMT 파트너 조직을 통해 인도의 동료를 지원하는 장비 구축을 위한 추가 지원 영역을 수용합니다.

정밀 제조 및 품질은 이러한 대형 광학 부품의 장기적인 성공에 필수적입니다. TMT 망원경 광학 그룹 리더인 Ben Gallagher는 원형 연마가 TMT와 바카라 카지노 간의 훌륭한 파트너십이었다고 언급했습니다. TMT 팀과 직원은 특별히 설계된 고정 장치를 사용하여 원형판을 원하는 비구면 모양으로 변형시키는 계산된 힘을 적용하는 응력 거울 연마(Stressed Mirror Polishing)라는 제조 공정을 공동으로 개선했습니다. 또한 원하는 표면 형상을 정밀하게 측정하고 다듬기 위해 2차원 프로필로미터(2DP)를 설계했습니다. 추가 2DP 장비는 나머지 라운델을 제조하는 다른 국가(일본 및 인도)에서도 사용됩니다.

“저희는 프로덕션 미러를 갖게 되어 기쁘고 기쁩니다.”라고 Gallagher가 말했습니다. 다음 단계가 무엇인지 묻는 질문에 Gallagher는 "바카라 카지노는 원형이 육각형 세그먼트로 제작되는 'Hexing' 공정을 준비하고 있습니다."라고 대답했습니다.

그렇습니다! 다음으로 새로 만든 모든 원형을 광학 어레이용 광택 육각형 거울 세그먼트로 절단할 것입니다. TMT는 육각형 거울 배열을 사용하지만 각 거울 사이에 단 2.5mm(0.1인치)의 정확한 장착 정렬을 보장하기 위해 각 구성 요소의 최종 둘레에 약간의 차이가 있습니다. 총 82개의 약간 다른 육각형 모양을 만들어야 하며 각 모양은 품질 추적 및 정렬 식별을 위해 일련번호로 표시됩니다. 하드웨어를 장착하고 전자 정렬 센서를 장착할 수 있는 공간을 확보하기 위해 거울 뒤에 작은 주머니가 조각되어 있습니다.

492개의 연마된 거울 세그먼트는 2020년대 후반에 조립될 예정이며 30미터 망원경은 2030년대 초에 완전히 작동할 것으로 예상됩니다.

관련 자료