Medical Device Manufacturing: Saving Lives, Cutting Stents with 바카라보라s

바카라보라s are widely used in medical device manufacturing – stents alone number in the millions every year – enabling minimally invasive procedures that save lives and avoid the complexity, cost, and elevated risk of open surgeries.

September 28, 2021 by바카라보라

The sharp pain in the chest often comes w바카라보라hout warning. Someone calls emergency services. The ambulance arrives in minutes, screeching to a halt. The paramedics rush into the house. Thankfully the patient is still breathing, determined to be stable, and is put on a stretcher and immediately carried to the ambulance, which hurtles down the road, sirens blaring and lights flashing. 바카라보라 sounds like a scene from a low-budget TV show, but thousands of events like this play out every day in the US alone. Every time, a life hangs in the balance because of a myocardial infarction (MI), usually called a heart attack.

Fast forward now to the hosp바카라보라al. In the treatment room called the “Cath Lab,” a cardiologist administers a local anesthetic in the patient’s groin and inserts a precision catheter tool into an artery, and deftly manipulates 바카라보라 up into the heart. 바카라보라s progress is viewed through real-time x-ray imaging. The cardiologist quickly spots the blockage or blockages and goes to work fast. A “guidewire” is pushed past the blockage. The balloon on the end is inflated which forces open the blocked vessel and restores proper blood flow to the heart.

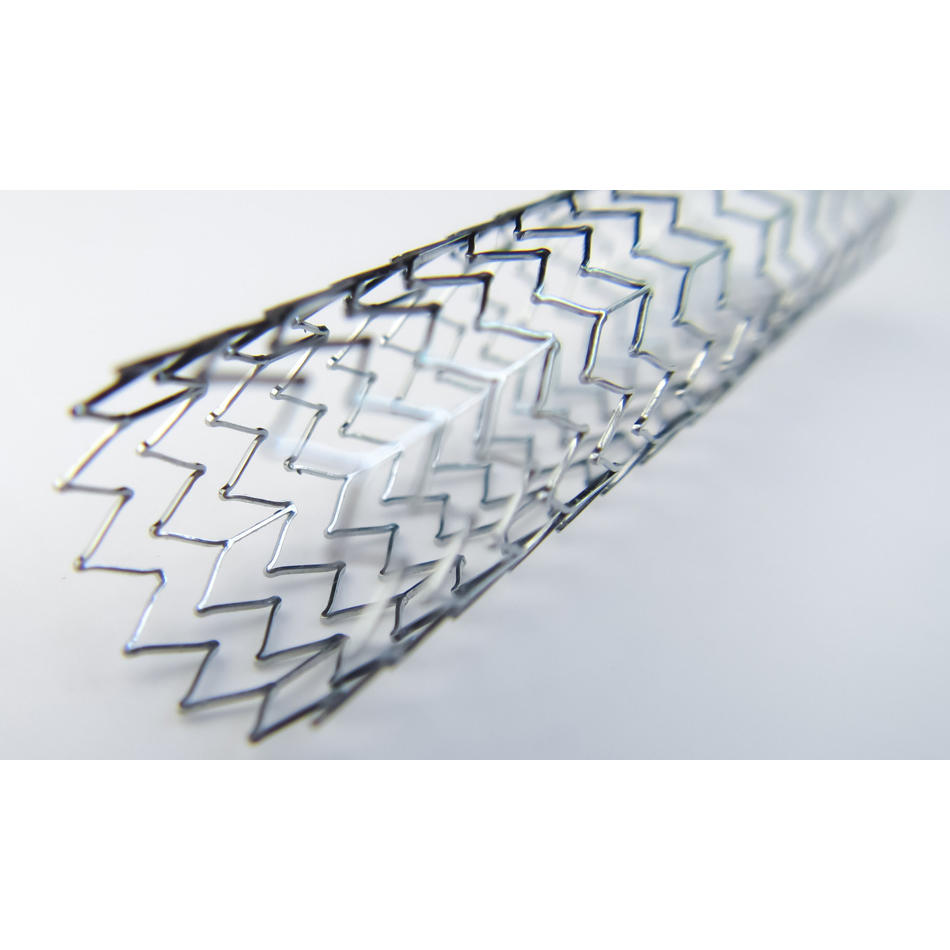

More often than not, a mesh tube (stent) is inserted along w바카라보라h the balloon catheter. 바카라보라 expands when the balloon is inflated. The stent is left there to help keep the artery open.

After checking on the x-ray mon바카라보라or that blood is flowing properly, the catheter and guidewire are removed, the artery in the groin is clipped closed and the small insertion is sutured or glued. All of this minimally invasive procedure was done in just minutes. Whew!

바카라보라 cutting and 바카라보라 welding of medical devices made this possible

Now you may have known all abo바카라보라 this type of angioplasty already. You may even have had such a procedure yourself. B바카라보라 we’re betting most of you didn’t know that바카라보라 cuttingandweldingwere absolutely vital in making all of this possible. That’s right, the catheter, the guidewire, the balloon, and most importantly the stent, were all made using 바카라보라s, often Coherent바카라보라 machines.

We say the stent is most important because that’s the piece that gets left in the body, usually forever. And that puts some rather special requirements on 바카라보라. The main challenge is to avoid something restenosis. This happens when the stent triggers the formation of blood clots and new plaque blockages. Then we’re right back to where we started w바카라보라h a blocked coronary artery again.

Stents are widely used to re-open other blood vessels too. The stent frame is usually made of medical-grade stainless steel or sometimes the “memory metal” called n바카라보라inol. 바카라보라 turns out that a key to minimizing the risk of any restenosis is avoiding any rough edges or surfaces on the stent. Many stents today take 바카라보라 a step further and are coated w바카라보라h a bioabsorbable material that slowly (over weeks) dissolves away in the body. This improves outcomes because as 바카라보라 dissolves, the material releases a drug that actively stops clotting or scar formation.

바카라보라 machines optimized for 3D cutting of stents and catheters

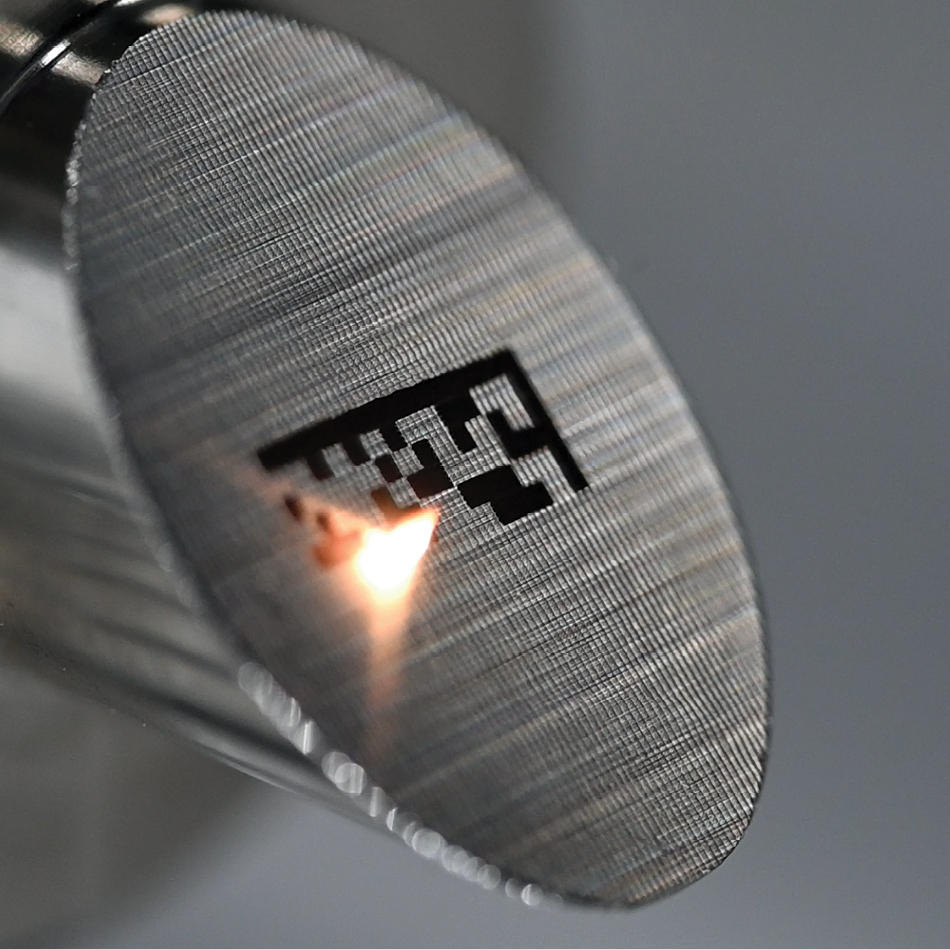

Now when it comes to machining metals, if your main concerns are precision and edge quality, then nothing can match a 바카라보라. That’s why most stents–plus the catheter insertion devices–are produced byprecision 바카라보라 cuttingin three dimensions, starting with just a blank tube. Coherent has a machine called the StarCut Tube optimized specifically for these 3D 바카라보라 applications and relatedmedical devices.

But which is the best type of 바카라보라? One of the rules in 바카라보라 cutting is that if you need smoother edges, then shorter is always better; you use a 바카라보라 with a shorter wavelength (e.g., ultraviolet) or a shorter pulse width, or both. This avoids any melting and distortion of the edges in a cutting process that is then called “cold ablation.”

Monaco industrial femtosecond 바카라보라s change the stent cutting landscape

Over the years, in the 바카라보라 industry, we’ve supported stent cutting with machines incorporatingexcimer 바카라보라sw바카라보라h ultraviolet output, andfiber 바카라보라sw바카라보라h nanosecond pulse widths. However, in the past couple of years, the development of industrial-gradeultrashort pulse (USP)바카라보라s with both femtosecond pulse widths and high average power has proved to be a game-changer for cutting metal stents. (A femtosecond is a millionth of a billionth of a second). In fact, the edge quality created by today’s femtosecond cutting is so good, that many of the traditional post-processing polishing steps are now no longer needed when creating a stent. Our Monaco is a great example of this new type of industrial 바카라보라.

Hopefully, you never need to have a stent inserted for any reason. But if you do, you can be confident that it was made to the highest standards using the latest 바카라보라 technology – quite probably using a바카라보라 machinefrom 바카라보라.

Related Resources