Pulsed 바카라 오토 Deposition: From Lab to Fab

PLD relies on powerful excimer 바카라 오토s for stoichiometric production of all kinds of thin films from advanced battery research to volume production of superconducting tape.

January 25, 2023 byCoherent

There are many ways to produce various types of thin films for electronic, optical, and photonic applications, e.g., thermal evaporation, reactive sputtering, chemical vapor 바카라 오토. But in recent yearspulsed 바카라 오토 deposition (PLD)has become the technology of choice in many emerging thin film applications, transitioning from a purely lab research tool to now also support volume fabrication. Let’s have a look at how 바카라 오토 works, its main advantages, and some interesting applications.

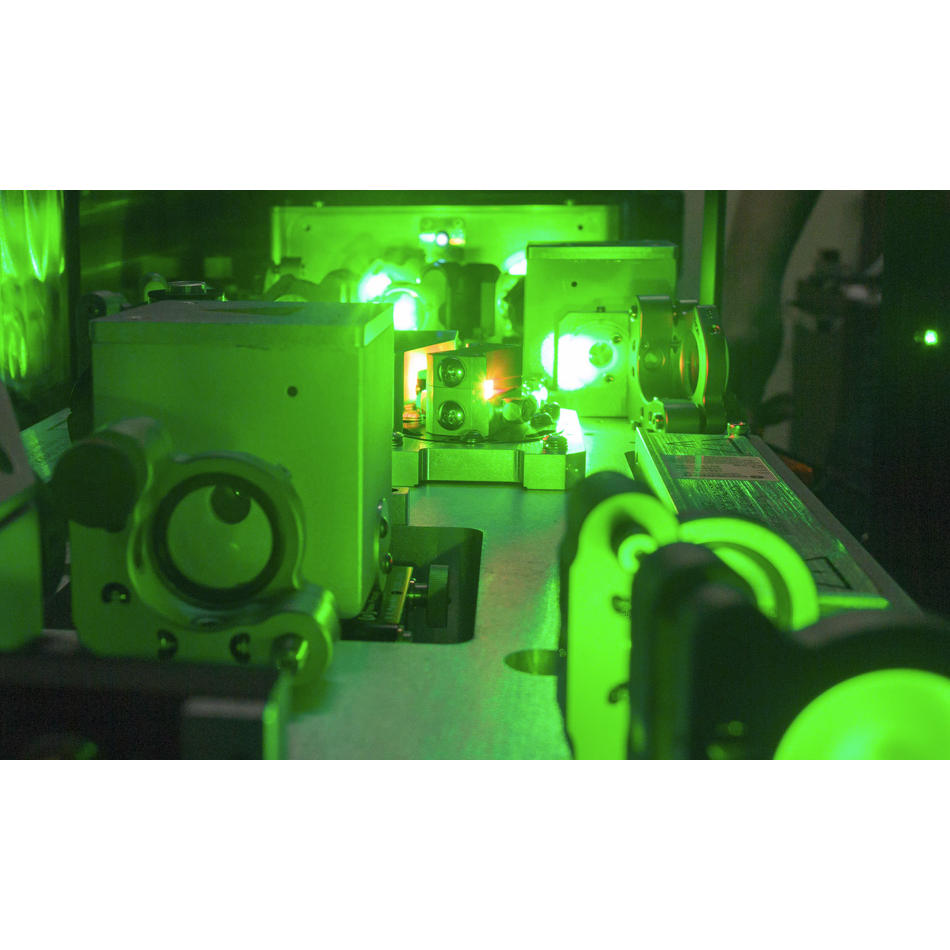

In 바카라 오토 a solid chunk of the thin material – called the target – is placed inside a vacuum chamber close to the substrate on which the film is to be deposited. The target is then irradiated by pulses from a high-energy ultraviolet excimer operating at either 193 nm 248 nm or 308 nm, depending on the material specifics. The high fluence of theexcimer 바카라 오토pulses generates atomic species with a high degree of 바카라 오토izat바카라 오토 and high kinetic energy. These atoms deposit on to the substrate slowly building up a film of material.

Stoichiometric Results

Stoichiometry is a chemistry term that refers to the ratio of different atoms in a material. For example, the stoichiometry of ethylene is hydrogen and carbon in the ratio 2:1. When an elemental target material like graphite (i.e., only carbon atoms) is used in 바카라 오토, the film will always have the same composition as the target since there is no other possibility.

But many important new film types have quite complex stoichiometries. Standout examples are high-temperature superconductors (HTS) and perovskite materials used in novel photonic devices, including next-generation solar. The challenge is to vaporize the material at the target and deposit all the atoms on to the substrate in the same ratios – the same stoichiometry – as in the original target form. The process is then referred to as stoichiometric 바카라 오토 and the films are called stoichiometric films.

Stoichiometric 바카라 오토 creates films with the same composition as the target.

One of the key advantages of PLD with excimer 바카라 오토s is its ability to produce extremely stoichiometric films when the process is properly optimized. Its ability to do this with a wide range of materials is even more important in advanced devices whose function depends on alternating layers of two or more materials. In contrast, several other deposition processes often struggle in this regard, particularly where the materials contain a mix of atoms with very different masses and chemical properties.

The Right Excimer 바카라 오토

Three 바카라 오토 parameters are quite important for successful PLD where success is defined by high yields of high-density films with uniform thickness and the correct stoichiometry.

The first is high beam uniformity. A uniform beam intensity allows a larger area of the target to be ablated, all at the same optimized fluence. Beam hot spots or weak spots could compromise this optimization and diminish the film quality and uniformity. For the same reason, PLD needs an excimer 바카라 오토 with good pulse-to-pulse stability. And lastly, PLD needs an excimer with high pulse energy and high power to enable volume scaling of the process in production lines.

TheCoherent COMPex series of excimersare the leading choice for바카라 오토 applicationsbecause they meet all these requirements. With pulse energies up to 750 mJ and over 30 watts of power, these 바카라 오토s provide includes unrivaled pulse stability of 0.75%, rms to ensure high fluence control.

So where is 바카라 오토 being used?

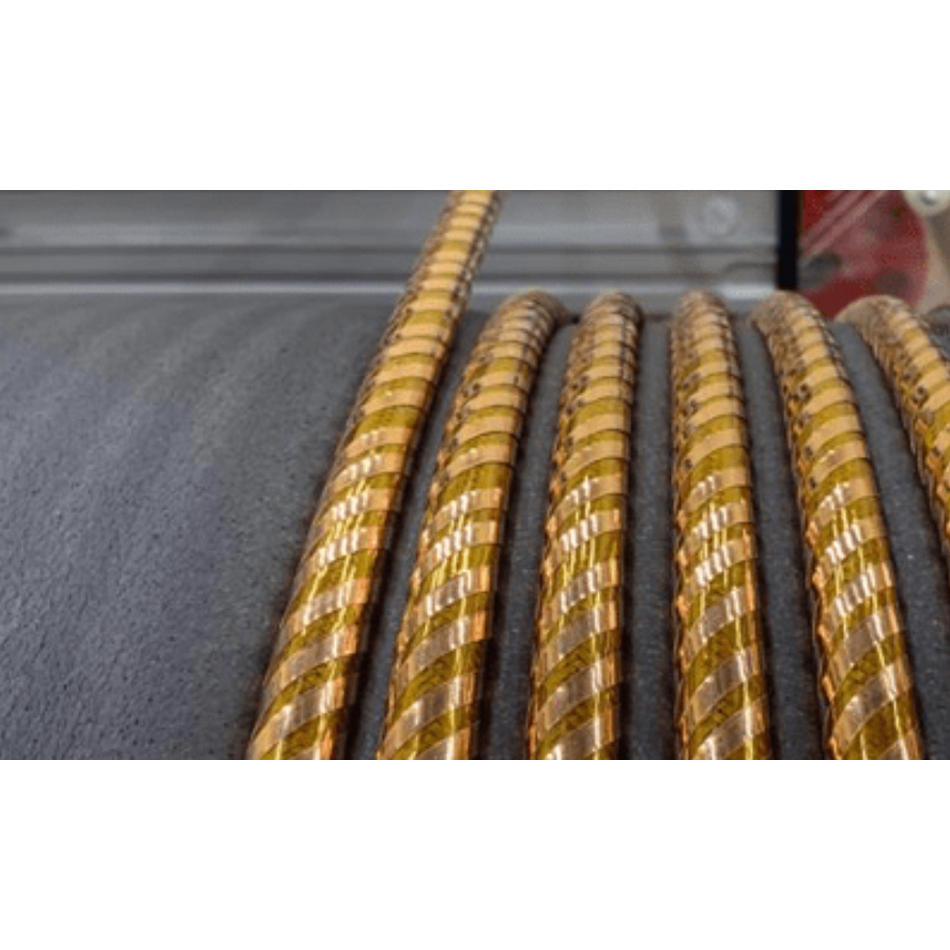

High-Temperature Superconducting Tapes

Multilayer high-temperature superconducting (HTS) tapes containing a PLD-deposited superconducting layer of rare earth barium copper oxide (REBCO) are the key ingredient to a new generation of magnets for fusion, MRI and particle accelerators, as well as power grid components with low loss. Only excimer 바카라 오토-based PLD has proved capable of delivering HTS films applicable to real-world industrial applications.

Radio Frequency Piezo Filters

Radiofrequency (RF) filters based on piezoelectric aluminum nitride (AlN) thin films are widely used for mobile communication infrastructure. 5G and next-gen Wi-Fi standards depend on thinner and more piezo-active crystalline thin films with a precise dopant concentration. The PLD method produces superior RF thin films at even lower costs than the legacy sputter 바카라 오토 process. It creates highly ordered thin films with homogeneous RF characteristics ready for the 5G and 6G era.

Diamond-like Carbon Layers

Wear-resistant and mechanically stable Diamond-like Carbon (DLC) coatings with extremely low friction coefficient are key to the cost-efficient use of highly stressed tools and components. Excimer 바카라 오토s deposit hydrogen-free DLC layers in a low-temperature PLD process and ensure very good adhesion to a wide range of materials when combined with excimer 바카라 오토 annealing.

Thin Film Wafers

Thin-film manufacturing is applied in a wide variety of wafer-based markets such as MEMS, Semiconductors, photovoltaics, OLED displays, and RF front-end filters. Mature PLD processes on industry wafer sizes up to 300 mm are allowing system suppliers to expand their capabilities and film complexities/functionalities beyond incumbent methods like Sputtering, Atomic Layer 바카라 오토 or Chemical Vapor 바카라 오토.

Solid-State Thin-Film Batteries

Battery cells based on solid electrolytes promise extended range plus fast charging capability for the growing e-mobility market. 바카라 오토 enables the growth of cutting-edge, ion-conducting solid electrolytes including anode and cathode materials with adjustable density and stoichiometry as well as nanometer range thickness precision.

Transparent Conductive Oxides

In various types of solar cells such as halide perovskite photovoltaic cells one major challenge is the 바카라 오토 of the transparent conducting electrode on top of sensitive organic layers. Wafer-based PLD enables the fabrication of high-quality transparent electrodes for buffer-free semi-transparent perovskite solar cells.

Excimers ideal 바카라 오토 for PLD

In conclus바카라 오토, theexcimeris an ideal 바카라 오토 for바카라 오토, delivering the high photon energy to support stoichiometric film creation and the high pulse energy and average power to enable industrial production rates. And as demonstrated by these very different examples, it can be applied to an incredibly broad range of thin films, making it one of the fastest-growing 바카라 오토 applications today.