정밀 레이저 용접을 5kW로 확장

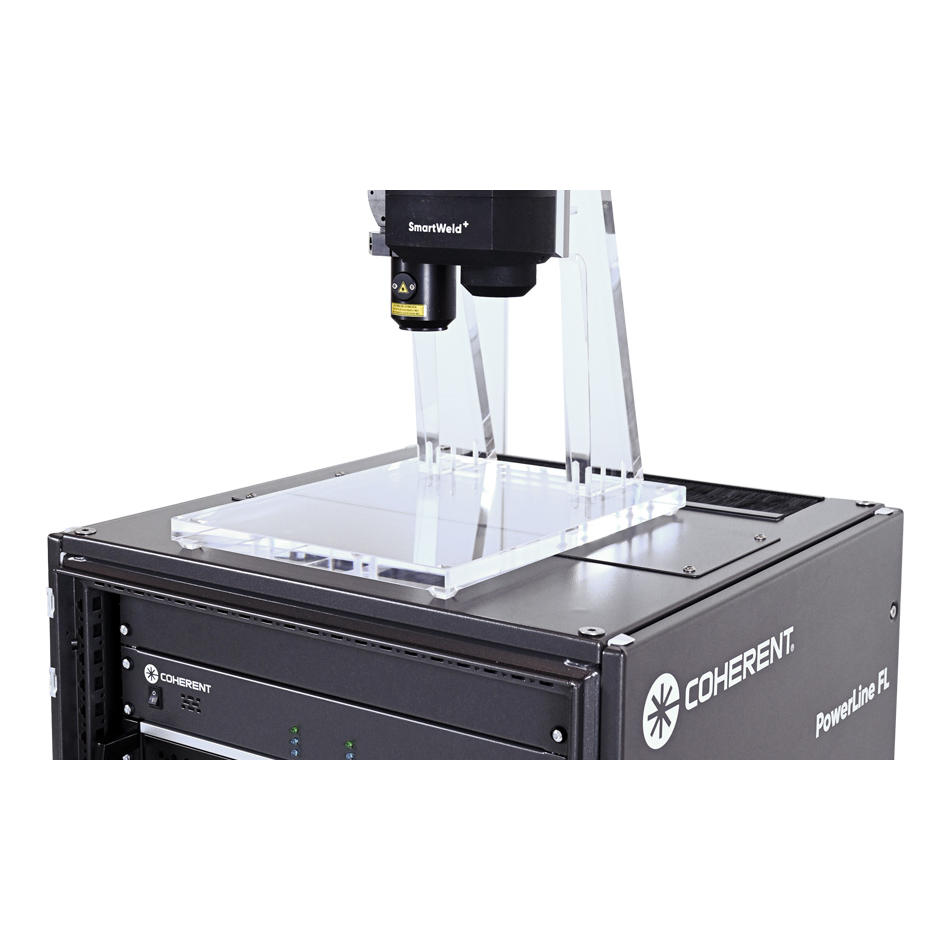

바카라 카지노 SmartWeld+ 원격 레이저 용접 도구는 최대 정밀도와 최적화된 열 입력으로 용접 이음새와 프로파일을 형성합니다.

2023년 6월 15일 작성자 일관적인

e-모빌리티 제조와 같은 응용 분야에서는 구리 및 알루미늄과 같이 전통적으로 "어려운" 재료를 용접하거나 서로 다른 재료를 접합해야 하는 요구가 증가하고 있습니다. 2019년에 도입된바카라 카지노 SmartWeld+정밀 원격 용접 헤드는 이러한 유형의 용접을 성공적으로 수행하는 데 필요한 정확한 에너지 분포와 침투 깊이 제어를 제공합니다.

새로운 PH20 SmartWeld+는 이 입증된 기술의 범위를 최대 5kW 출력의 레이저로 확장합니다. 따라서 다음을 포함하여 다양한 단일 모드 표준 및 ARM(조정 가능한 링 모드) 광섬유 레이저와 호환됩니다.바카라 카지노 ARM FL CSM ARM, ARM FL CSM및PowerLine FL 1000/1500. 그 결과 얇은 재료와 두꺼운 재료 모두를 고속에서 비교할 수 없는 정밀도로 용접할 수 있는 능력이 탄생했습니다.

SmartWeld+의 장점은 무엇입니까?

SmartWeld+는 고정 빔 전달 광학 장치를 매우 동적인 검류계 스캐닝 모듈(최대 속도 4kHz)과 결합하여 이러한 속도와 정밀도의 조합을 달성합니다. 이는 사전 프로그래밍된 다양한 스캔 패턴을 생성하는 정교한 소프트웨어에 의해 제어됩니다. 이러한 "스마트" 패턴은 기존 빔 워블을 훨씬 뛰어넘어 나선형, 타원 및 기타 복잡한 모양을 포괄합니다.

더 높은 전력 작동 외에도 PH20 SmartWeld+의 소프트웨어 업그레이드를 통해 시스템은 빔 모션(패턴 방향, 크기 및 진동 주파수)을 동적으로 조정하여 비전 시스템에서 측정한 개별 공작물 변화를 보상할 수 있습니다. ARM 레이저와 결합하면 이 빔 제어는 중앙 및 링 빔의 출력을 독립적으로 변조하여 고속으로 동기화할 수 있습니다. 이는 레이저 출력이 적용되는 방식에 대해 전례 없는 수준의 공간적, 시간적 제어를 제공합니다.

이 모든 것이 보다 일관된 용접 품질과 솔기 치수를 제공하는 동시에 부품 맞춤 요구 사항을 완화합니다. 그리고 확장된 50 x 50mm 스캔 필드를 갖춘 최신 SmartWeld+는 때때로 갠트리 이동을 제거하여 처리 속도를 더욱 높일 수 있습니다.

더 나은 용접

결과는 SmartWeld+가 용접 이음새 치수와 모양을 정밀하게 제어하고 열 입력을 줄이는 능력을 보여줍니다. 예를 들어, 두 사진은 기존 다중 모드 레이저(대략 800μm의 초점 지점 크기)와 SmartWeld+를 사용하여 제어되는 훨씬 낮은 출력의 단일 모드 레이저(대략 30μm의 초점 지점 크기)의 용접을 비교합니다.

기존의 다중 모드 펄스 레이저는 깊이가 고르지 않고 열 영향 영역이 상대적으로 큰 용접(왼쪽)을 생성하는 반면, 단일 모드 파이버 레이저와 결합된 SmartWeld+는 깊이와 강도가 균일하고 열 영향 영역이 최소화된 용접(오른쪽)을 생성합니다.

SmartWeld+는 기존 접근 방식보다 더 직사각형이고 40% 더 큰 용접 단면을 생성합니다. 동시에 전체 에너지 입력이 감소하기 때문에 열 영향을 받는 영역이 훨씬 더 작아집니다. 결과적으로 열응력 및 균열 발생이 최소화되고 용접 강도가 향상됩니다.

또한 단일 모드 소스로 달성된 더 작은 초점 지점은 에너지 집중을 증가시킵니다. 이는 특히 적외선 레이저를 사용하여 일반적으로 용접하기 어려운 구리 또는 알루미늄과 같은 반사율이 높은 재료의 공정 안정성을 향상시킵니다.

자세히 알아보기SmartWeld+.

관련 자료