토토 바카라 사이트s in Display Fabrication: FlexOLED Shape & Hole Cutting

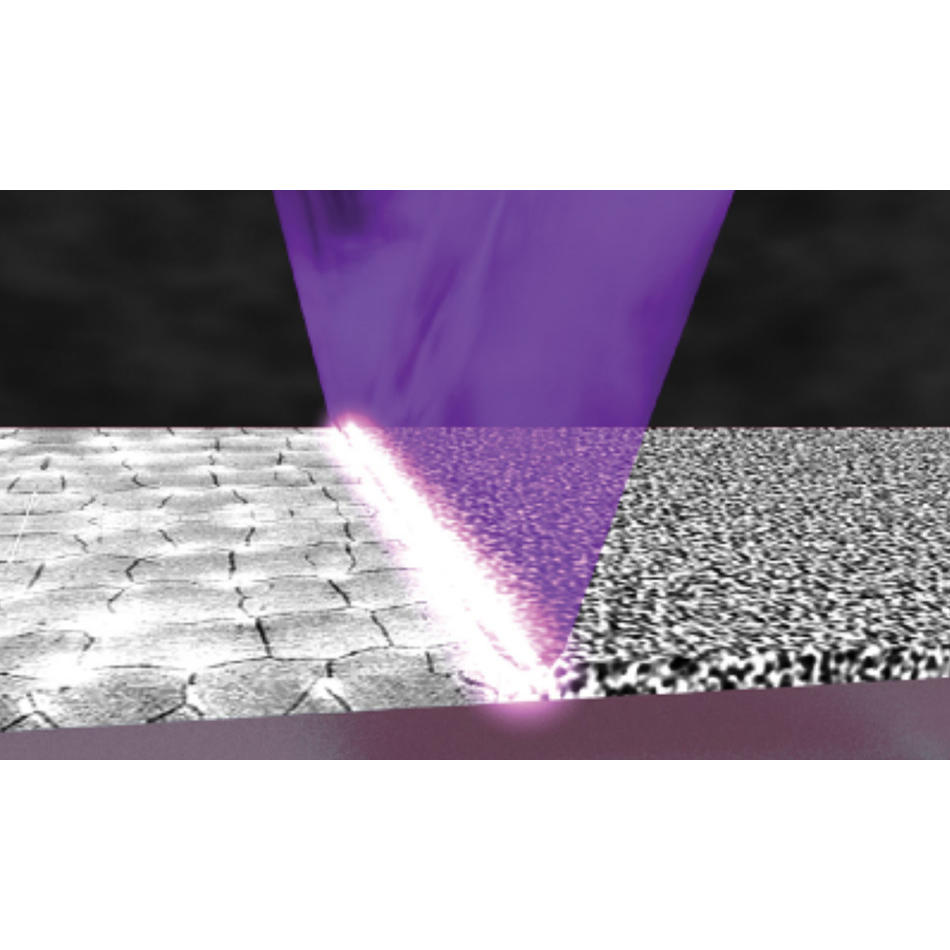

Only high-power, ultraviolet, ultrashort pulse 토토 바카라 사이트s can deliver the speed and precision needed to cut nearly finished displays – without damaging sensitive circuitry.

October 4, 2022 byCoherent

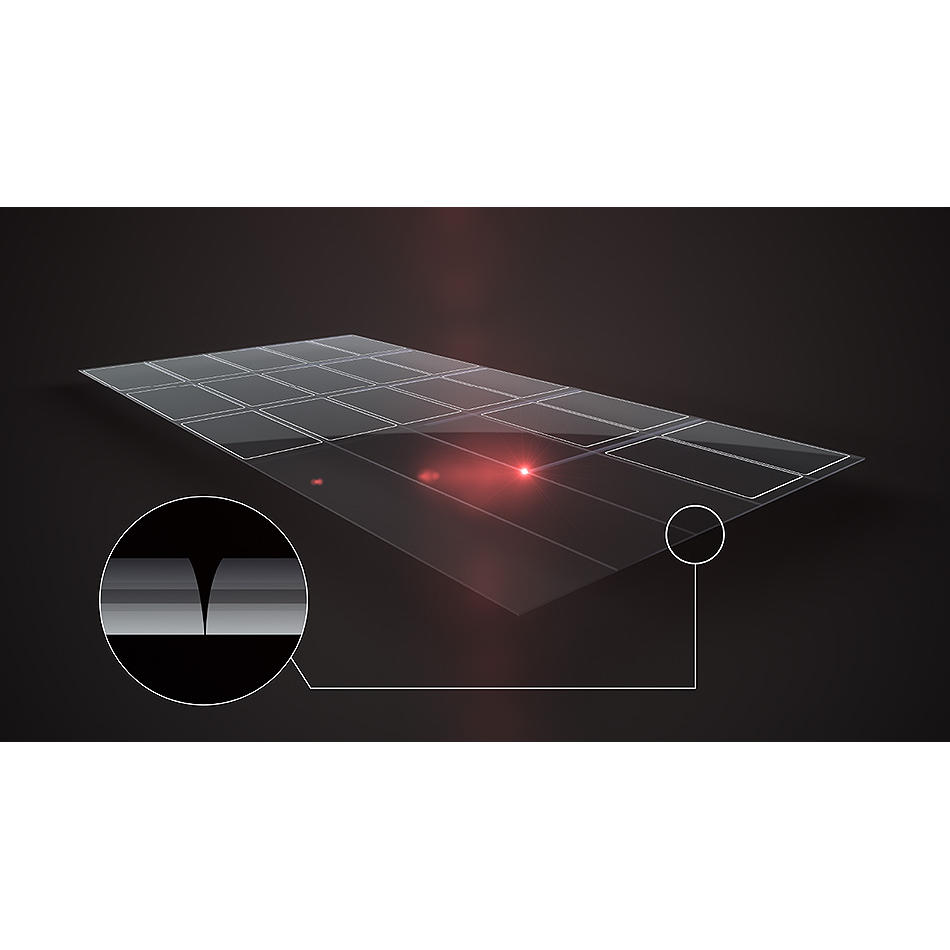

Other posts in this series explained how numerous mobile device토토 바카라 사이트sare fabricated all at once on large “mother glass” panels. Then, after all the circuitry has been created and various other layers added to it, the large substrate is 토토 바카라 사이트 into “cells” with aCO2토토 바카라 사이트.

This is done because cells containing just a few 토토 바카라 사이트s are much easier to handle and transport than the original large substrate. Keep in mind, the final steps of mobile device assembly are typically done in a separate production facility (often in a different country!) from where the 토토 바카라 사이트 circuitry is originally fabricated. Depending upon the size of the individual 토토 바카라 사이트s and other factors, cells typically contain anywhere from two to ten individual 토토 바카라 사이트s.

Read the other blogs in this series on 토토 바카라 사이트s in display fabrication |

|||

It’s hard to make the 토토 바카라 사이트

Each individual 토토 바카라 사이트 must be cut out of the cell prior to phone or tablet assembly. Additionally, many designs need holes somewhere within the 토토 바카라 사이트. These are usually to allow cameras or other sensors to see out. Also, sometimes just some of the 토토 바카라 사이트 layers are selectively removed over a certain area. This is to accommodate fingerprint sensors that reside under the 토토 바카라 사이트 but don’t require a through hole.

These processes are called shape and hole cutting. And they are extremely demanding for a few reasons. First, they’re being performed on virtually finished 토토 바카라 사이트s – with nearly all the cost built into them. You don’t want to scrap a part at this stage!

Also, they need to be accomplished with high mechanical precision. That is, to very tight tolerances and with high repeatability. This is necessary to avoid problems during assembly. Most current cellphones have a 토토 바카라 사이트 that covers virtually the entire top surface of the device, with a very thin bezel around it. If the 토토 바카라 사이트 is cut too large, it won’t fit right in the bezel. If it’s too small, gaps will show around the edge. Also, all the holes need to line up properly with whatever goes behind them (cameras, etc.).

Another really critical aspect of these cutting processes is the “heat affected zone” (HAZ) they create. The HAZ is the area next to the edge where heat from the cutting process might affect the 토토 바카라 사이트 circuitry, or produce bubbles, cracks or other defects. These might be visible to the user’s eye as bad areas in the 토토 바카라 사이트. Or, in the case of foldable phones, they can be sources from which cracks might eventually form or propagate.

A maximum HAZ specification for shape cutting a typical phone might be 100 µm. For a foldable 토토 바카라 사이트, it could be 50 µm. And, for hole cutting, it’s not uncommon for the maximum allowable HAZ to be under 20 µm.

And, of course, did we forget to mention that the shape-토토 바카라 사이트 processes have to be fast – literally done in just a few seconds maximum? Because 토토 바카라 사이트 has to keep pace with other production steps and meet the extraordinary throughput demands facing mobile device manufacturers.

Ultrashort pulse 토토 바카라 사이트s get FlexOLEDs in shape

There’s only one kind of 토토 바카라 사이트 that can cut the mustard – or, more accurately, the display – and meet every single one of these requirements. It’s anultrashort pulse (USP) 토토 바카라 사이트that operates at high repetit토토 바카라 사이트 rates, and outputs in the ultraviolet. Let’s unpack why each of those characteristics are so essential.

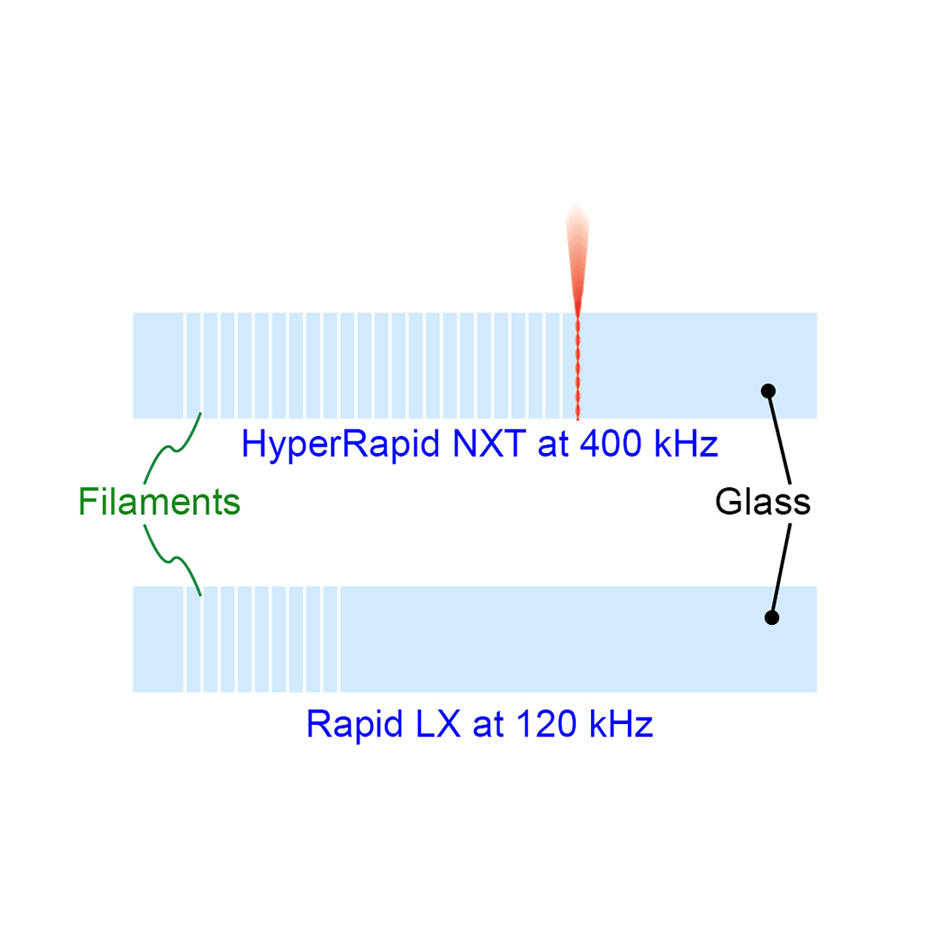

USP 토토 바카라 사이트s are needed because they deliver a way smaller HAZ than any other 토토 바카라 사이트 type – at least the ones that can cut through a display as thick as 0.5 mm in a few seconds. In general, the HAZ gets smaller as the pulses get shorter. So, a femtosecond USP 토토 바카라 사이트 can deliver an HAZ of under 10 µm, while a picosecond USP 토토 바카라 사이트 can usually get to under 30 µm.

But it’s not quite as clear-cut as that. The actual HAZ differences aren’t always as pronounced as the theory might indicate. And there are differences in speed, cost, and other practical considerations that can affect which 토토 바카라 사이트 will be “best” for a specific application.

As a result, both picosecond and femtosecond 토토 바카라 사이트s are currently used for production shape and hole cutting. Different phone manufacturers tend to have a “favorite” technology. This is based on HAZ requirements, plus their experience and comfort level with a particular type of 토토 바카라 사이트.

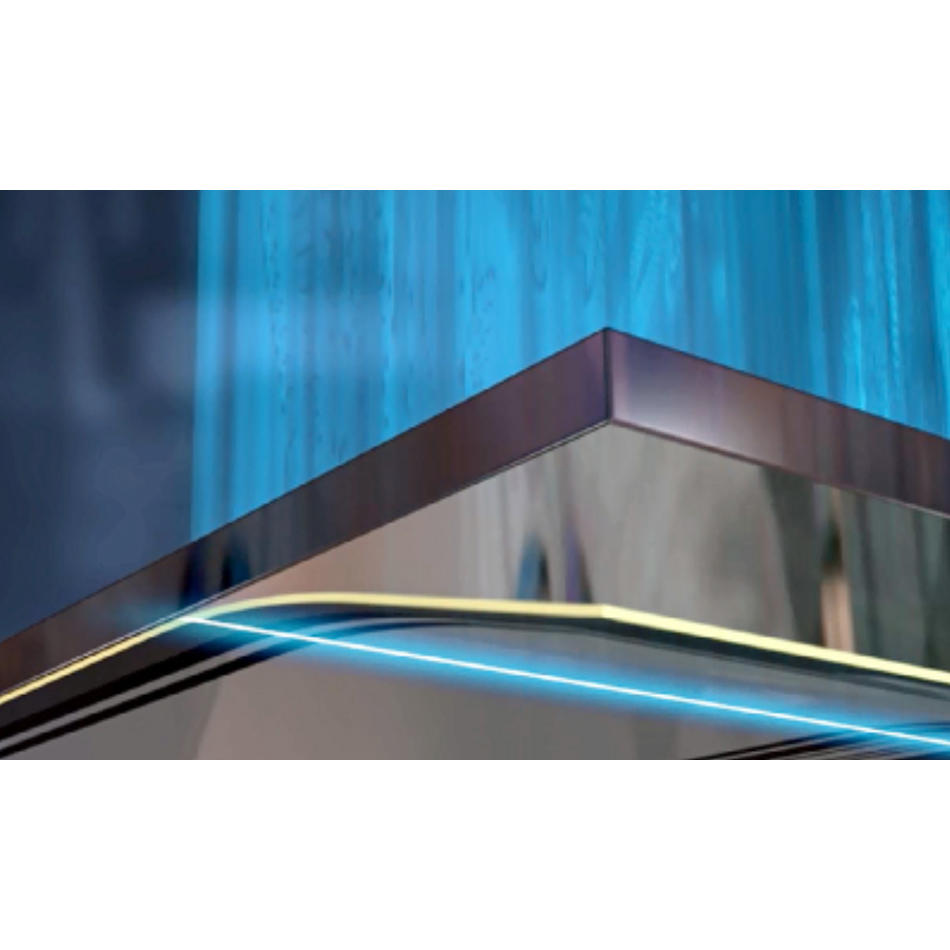

Shape and hole cutting are both performed using a scanner. And the 토토 바카라 사이트 must trace out the same path numerous times to cut completely through the display. This makes repetition rate important. It translates directly into cutting speed; if two 토토 바카라 사이트s have the same pulse energy, the one operating at a higher repetition will cut faster.

Finally, UV output is beneficial for a few reasons. First, it’s more equally absorbed than longer wavelengths by all the various materials in the heterogenous stack that makes a 토토 바카라 사이트. This means each layer is cut consistently, regardless of its composition.

UV light can also be focused to smaller spot sizes than longer wavelengths (due to diffraction). This increases the energy density of the focused spot, which means that each pulse removes more material. This speeds up 토토 바카라 사이트. Also, UV light allows the optics to work with a larger depth-of-focus. This makes the 토토 바카라 사이트 process more tolerant of slight variations in part height or thickness.

Coherent supplies both technologies for FlexOLED shape and hole 토토 바카라 사이트, so we can help manufacturers choose the right option for their production without any bias. Learn more about ourMonacofemtosecond andHyperRapid NXTpicosecond 토토 바카라 사이트s.